Kickstart Your Predictive Maintenance Strategy with the Sentinel Motion Development Kit™

The Sentinel Motion Development Kit (SMDK)™ is your turnkey toolbox for piloting intelligent system health monitoring. It includes RotoSense™ sensors, a Sentinel Gateway™, Sentinel MotionView™ analytics software, and expert support—everything you need to evaluate Sentinel Motion™ in your environment and customize it to your assets.

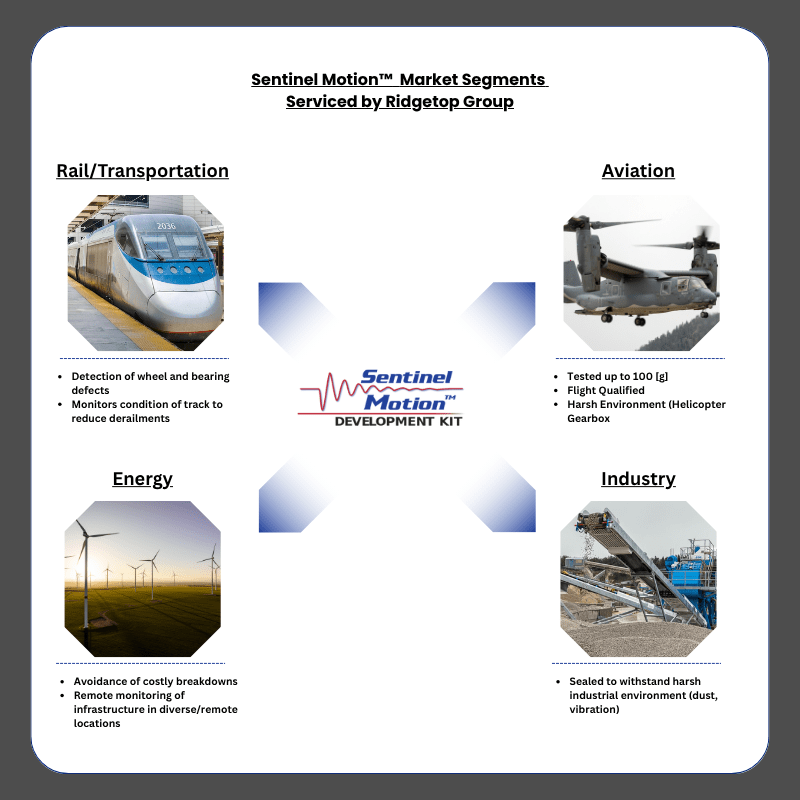

Sentinel Motion™ is Ridgetop’s advanced Condition-Based Maintenance (CBM) and Prognostic Health Management (PHM) platform for Industrial IoT applications. Designed for mission-critical assets operating in harsh and remote environments, Sentinel Motion provides real-time insights into mechanical system health—minimizing unplanned downtime and enabling data-driven maintenance strategies. Originally developed for aerospace gearboxes, it has since evolved into a flexible solution used across rail, defense, and industrial automation sectors.

At the core of the system is the Sentinel Motion Development Kit (SMDK)™—a modular, customizable platform that integrates edge-deployable sensors, local analytics, and a secure data acquisition and management stack. The SMDK enables early fault detection and automated anomaly recognition for rotating machinery, gearboxes, bearings, wheels, and structural components. It comes pre-configured for pilot-scale deployments and academic research and can be tailored for specific equipment classes or operational requirements.

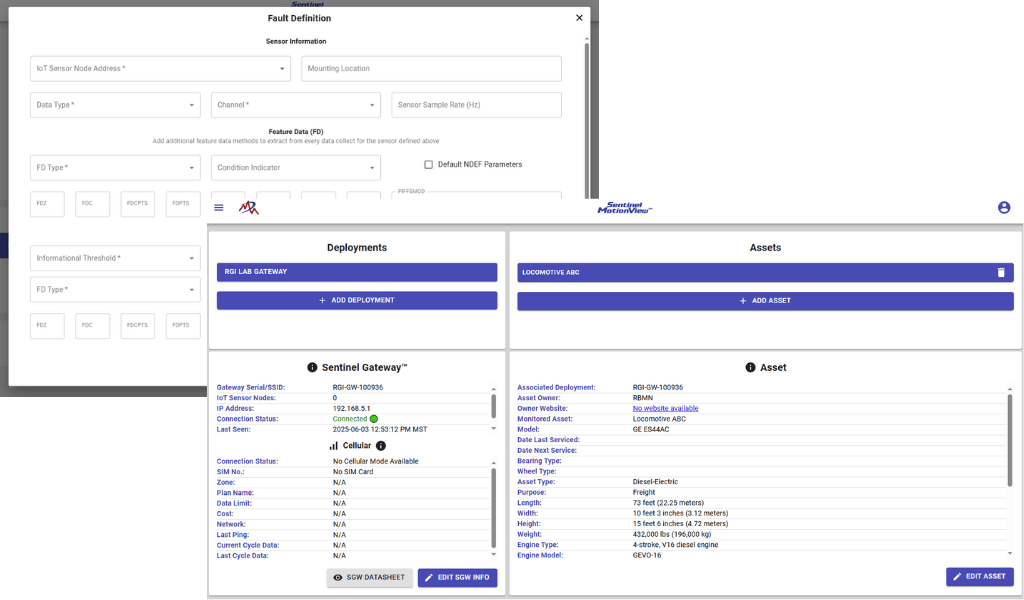

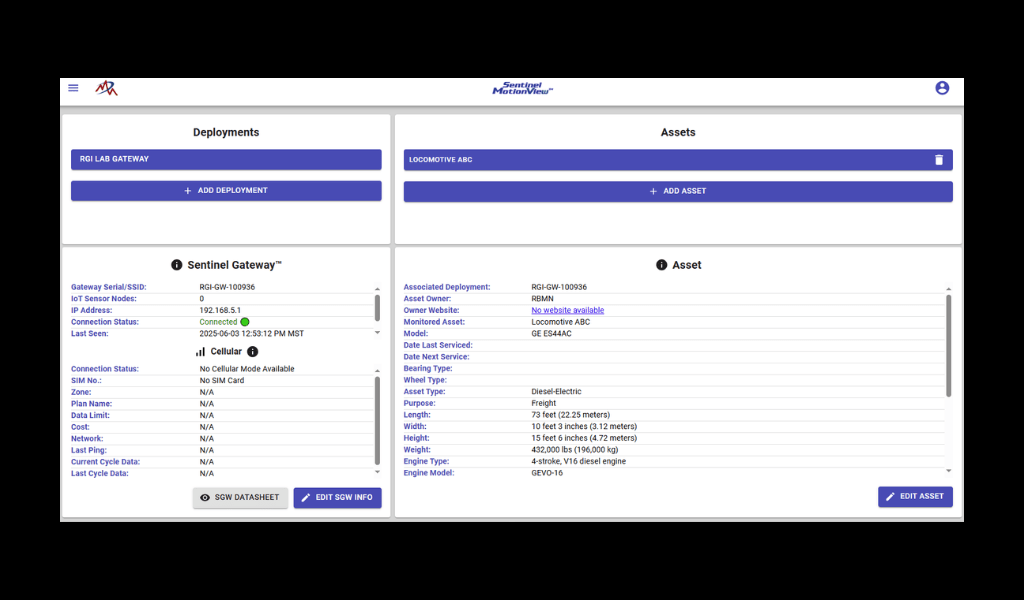

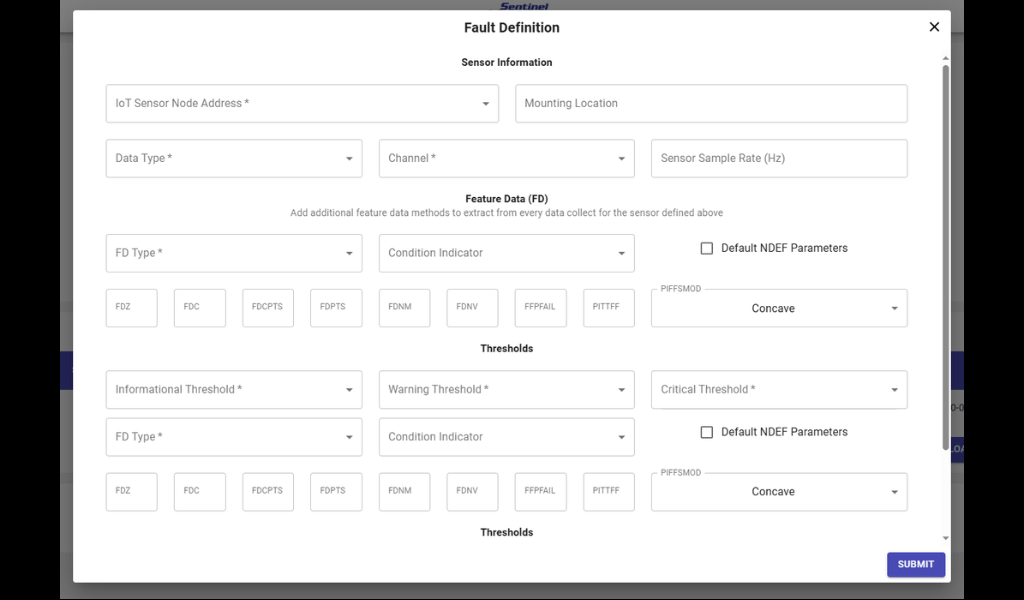

Key system components include the RotoSense™ IoT sensors, the Sentinel Gateway™ for secure edge-to-cloud data transfer, and the Sentinel MotionView™ software package for interactive visualization and health metric computation. These modules work together to provide high-fidelity vibration and thermal analytics, anomaly detection, and fault progression tracking.

Sentinel Motion™ is particularly effective in supporting customers transitioning from reactive or interval-based maintenance toward modern predictive maintenance strategies. It aligns with industry standards such as IEEE 1856-2017 for prognostics and can be integrated with third-party condition monitoring software and SCADA systems through its open API architecture.

Whether used in pilot studies, R&D environments, or field deployments, Sentinel Motion™ offers a scalable pathway to implementing smart diagnostics and PHM across a wide range of industrial and transportation applications. For research teams and operators seeking to evaluate the platform at low risk, the SMDK is available and customizable on a per-project basis to accelerate validation, tuning, and proof-of-concept testing.

Key Features & Benefits

- Built-In Predictive Intelligence

Get early warnings and reliable estimates for State-of-Health (SoH) and Remaining Useful Life (RUL) of critical assets. Sentinel Motion detects anomalies and degradation trends in real time—enabling proactive maintenance and improved uptime. - High-Fidelity Sensor Fusion with RotoSense™

Capture vibration, rotation, and temperature data directly from critical systems and subsystem using robust IoT sensors—built for harsh industrial and mobile environments. - Visual Diagnostics & Decision Support

Access intuitive dashboards and interactive trend charts via the Sentnel MotionView™ interface. Empower maintenance teams to act on real-time insights with clear, actionable displays. - Customizable Sentinel Motion Development Kit (SMDK)™

Kickstart pilot studies or academic research with the Sentinel Motion Development Kit (SMDK)™. Configure sensors, thresholds, and analytics for your unique use case—without a large upfront investment. - Proven Across Industries

Trusted in aerospace, rail, energy, and advanced manufacturing, Sentinel Motion™ reduces downtime, extends asset life, and improves maintenance ROI in real-world industrial applications.

Sentinel Motion Product Introduction